GHX classroom

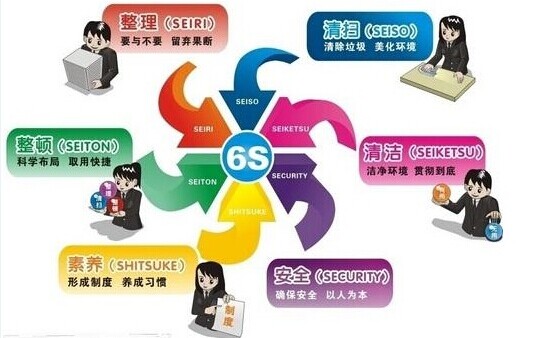

| 6S Management | |

|

"6S management" by Japanese enterprise of 5S expansion, is the modern factory effective field management concepts and methods, its effect is to improve efficiency, ensure the quality and make the work environment in a neat and orderly, prevention and safe. 6S nature is a kind of executive force of the enterprise culture, emphasize the culture of discipline, does not fear the difficulty, thought of do, do it well, as a basic 6S the work carries out, for other management activities to provide high quality management platform. 1. (SEIRI)--will work any item is divided into necessary and not necessary, in addition to have the necessary to stay, the others are eliminate. Objective: to make space, use of space, prevent misuse, shaping relaxed and place of work. 2. (SEITON)-the necessary to stay with items in accordance with regulations positions, and placed neatly to mark. Objective: to work be clear at a glance, and eliminate looking for items of time, very neat work environment, eliminate the backlog items too much. 3. (SEISO)-will workplaces visible and invisible swept clean place, maintain workplace clean, bright beautiful environment. Purpose: stable quality, reduce industrial damage. 4. (SEIKETSU)-will be collecting, rectify, sweeping through to the end, and institutionalized, often keep the external environment and beautiful state. Objective: to create clear the site, maintain above 3 S results. 5. (SHITSUKE)-every member form good habits, and abide by the rules work, training initiative spirit (also called the habitual). Objective: to cultivate a good habit, abide by the rules of the staff, build the team spirit. 6. (SECURITY)-pay attention to safety education members, every second safety first idea, and maybe prevent problems caused by misunderstanding. Objective: to establish a safety production environment, all the work shall establish in safe premise.

|

|